When it comes to bottles and closures, the neck is the upper part of the bottle that accommodates the closure. The closure always has to fit the neck. Let's learn more about threaded necks!

To find the best possible bottle/closure combination, we need to know a number of things. It is then necessary, if not compulsory to have some information on plastic bottle necks in order to choose the right cap.

Bottle neck: definition and measurements

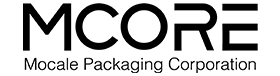

The neck of the bottle is defined by its total height, its inner diameter, its outer diameter and its thread.

The dimensions of a neck (expressed in mm)

28 DIN, 28 ROPP, 28/400, 28SP400: what does it all mean?

These designate different types of bottle necks.

GCMI (28/410, 28/400, etc...) and SP (28SP410, 28SP400, etc...) bottle necks

GPI and GCMI are the bottle necks' American standard, SP is the equivalent European standard.

They consist of two numbers separated by a slash or the letters SP:

1. The 1st number (for ex. 28) is the OUTER DIAMETER of the neck in mm (see "T" on the plan above)

2. The 2nd number (for ex. 410) refers to the thread configuration and height of the neck.

It is a standard type of thread established by the Glass Packaging Institute and the Society of Plastics Industry. 400 410 415 numbers refer to the number of thread turns around the bottle neck.

Attention : there can be features specific to certain bottle manufacturers

GPI / GCMI and SP types of neck are currently found on bottles used in the fields of cosmetics, human health or pharmaceuticals (for example the following Fidel Fillaud's ranges of bottles : Classic / Essentiel / Tall Boston Round / SHARP).

DIN (18DIN, 28DIN, 54DIN, etc…) and GL (GL18, GL28, GL45, etc…) bottle necks

DIN is the German standard. It refers to the standard size of the neck, to its height and diameter

GL is the equivalent French standard.

DIN or GL neck naming DIN ou GL are composed of a 2-digit number indicating the OUTER DIAMETER of the thread in millimeter - followed, or preceded by the letters DIN (Deutsches Institut für Normung) OR preceded by the letters GL.

DIN / GL types of neck are currently found on dropper bottles used in the fields of human health and pharmaceuticals, or cosmetics (for example Fidel Fillaud's "all-round" glass bottles and "aromatherapy" plastic bottles ranges).

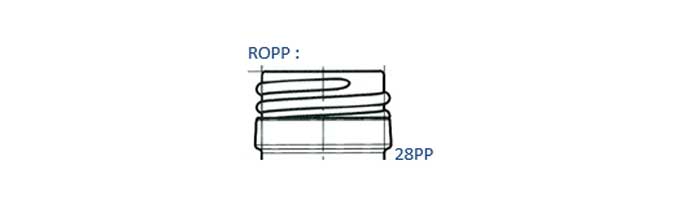

PP / ROPP (28PP, 28ROPP) bottle necks

The ROPP, "Roll On Pilfer Proof" necks, sometimes called PP for Pilfer Proof, are designed to receive a screw cap with a tamper-evident ring that breaks when opened for the first time.

ROPP / PP types of neck are currently found on bottles used in the fields of human health and pharmaceuticals (for example the following Fidel Fillaud's ranges of bottles : Sirop-Alpha and Pharma-Veral).

Some points to watch for when choosing your cap

Check all the dimensions of the neck, in particular the "H"dimension

Check the seal system between the neck and the inside roof of the closure

In the example below, the bottom skirt of the closure makes contact with the shoulder of the bottle. This is known as bottoming-out. As soon as you tip the bottle, the liquid leaks out!

Check that the cap fits the neck threads

Check the seal system between the neck and the inside roof of the closure

1. Pay attention to the tolerance: Neck dimensions can change depending on the material, the manufacturer and the manufacturing process, so it's important to pay attention to the manufacturing tolerance range of the closure AND the bottle

2. Beware of "false friends": Some necks have commonalities or similarities that can be misleading, so be careful.

3. Beware of self-sealing systems:

Reducer: if the neck diameter is too large, or on the contrary, too narrow, the reducer won't fit and the seal will not be ensured

Threaded self-sealing or flip caps: to ensure the seal, the sealing lip must perfectly match the inner diameter of the neck

Small focus on sealing lips

The two most current types of closure sealing lips are those named "standard" and "crab’s claw"

The "crab’s claw" has the advantage of adapting to a larger number of bottle necks and may allow the use of a seal, a gasket or reducer (subject to compatibility tests)

Two complementary tips

1. To make absolutely sure that your bottle/closure combination works, especially if you order from different suppliers, you need to conduct testing:

a. with the solution being conditionned

b. respecting the torques

2. Make sure that the neck of the bottle is clean and dry before screwing on.